This custom, hand-made, vinyl, Star Wars family window decal is now sporting the back of my car! And I actually made it myself! I will now show you how I did it, step by step!

To be fair, this decal set not really my own design. You can buy Star Wars family decals from ThinkGeek and other online stores. Although that particular set does not come with the AT-AT Walker. I had to make that myself using white vinyl electrical tape and a X-ACTO knife. Below is a photo of what my car window decals looked like just a few days ago.

The AT-AT Walker and blaster look like new because they were just remade last year. The original ThinkGeek decal set lasted way longer than the electrical tape did.

So when it came time to replace the set this summer, I wanted to come up with a better solution than electrical tape for the AT-AT Walker. I found self-stick vinyl sheets at my local craft store and decided to give it a try. Then I decided to try to make the entire set myself since I had these large vinyl sheets.

It’s possible to print directly onto these vinyl sheets, but I didn’t have a thin crisp outline image to start out with, so I printed on regular paper what I had at my disposal. But an outline showing exactly what needs to be cut out is what you need at this point.

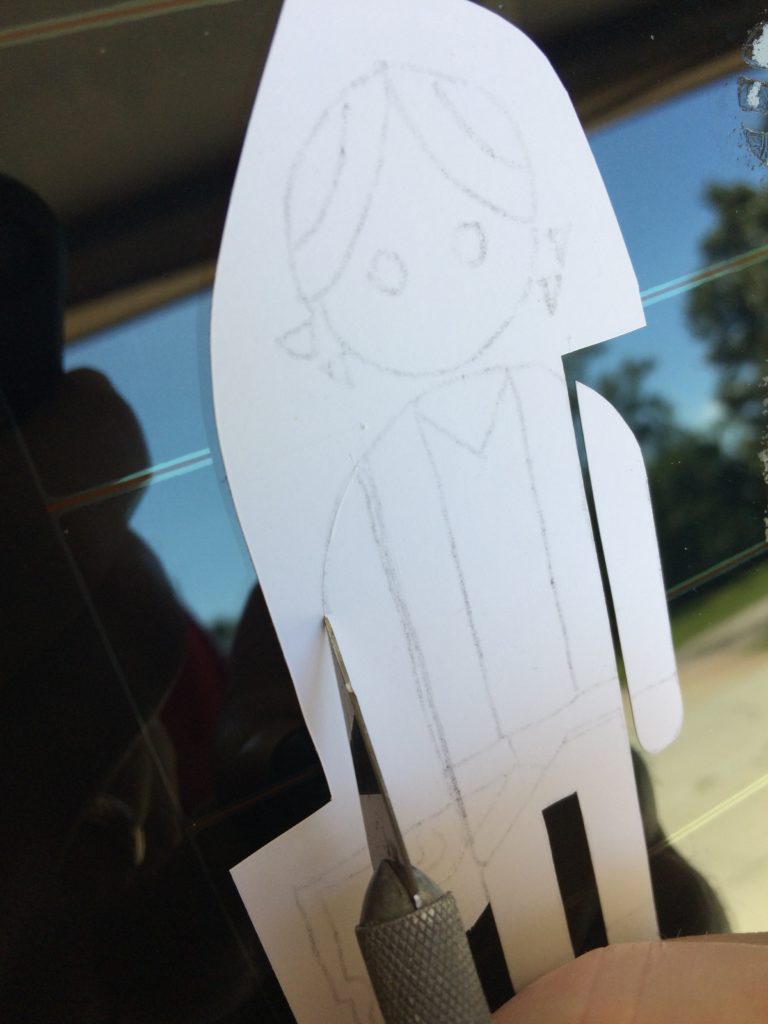

I decided to do one character at a time, so I cut out the first character. Again, this was printed on regular printer paper at the exact size you want on your window.

To transfer your cutout lines to the vinyl, carbon paper would be very useful. In the absence of carbon paper, a technique that works pretty well is to rub pencil on the back of the pattern.

And then trace the cutout lines on the front of the pattern held firmly on top of the vinyl sheet.

And now you have a light pencil drawing of the cutout lines there on your vinyl sheet.

Then you just cut out that part of the vinyl sheet.

And you prepare the window surface by scraping with a razor blade and washing with glass cleaner.

Then peel off the backing from the vinyl sheet and carefully align the character where you want it. Let it make contact in the middle and then roll the contact surface towards the outside edges to keep air bubbles from getting trapped inside.

Then start cutting with a X-ACTO knife and peeling away the waste material.

Getting perfectly straight lines and perfectly symmetrical curves takes some concentration and/or some artistic talent. But when it’s all said and done, these cuts don’t have to be perfect. Most people will be viewing them from about a car-length away.

The hardest cut-outs, I think, are the thin lines. Making them straight and symmetrical isn’t trivial.

Getting closer. This takes patience and a steady hand.

And the first character is all done!

Then repeat the steps for the second character.

And the third character.

And so on.

Until your entire family is complete. Plus any pets that you want to include.

Now I’m not sure exactly how long this craft vinyl material is going to last out in the elements. But I live in Florida and I don’t have any shade at work to park my car under. And we also have quite a bit of rain here in the summer months. So I will update this blog article as soon as I have an idea about how long this stuff lasts under these conditions.

That’s all! I hope this blog article ends up being useful to someone out there in Internet-land!

Thanks for your interest!

Kurt

Update: July 2017

I recently added a NASA Swarmie robot to the side windows of my car. What do you think?